Intubation stacking rack

We produce folding stacking racks, tube stacking racks and pallets for the world. We can help you choose the best storage solution. We have rich experience to provide you with one-stop service, including design, customization, production, and problem solving. We look forward to our cooperation.

Square tube stacking column introduction

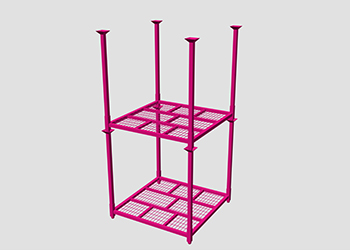

Square tube stacking column refers to the stacking column that uses square steel tube as the main supporting structure. It is widely used in storage shelves, logistics equipment, industrial storage systems and other fields. Compared with round tube columns, square tube columns have unique advantages in load-bearing capacity, stability, connection method, etc.

(1) Structural advantages

High bending strength: The square cross-section is more stable than the round tube when subjected to vertical force, suitable for heavy storage.

Easy to connect: The flat contact surface is large, which is convenient for welding and bolting.

Stable stacking: Square tube columns are not easy to roll when stacked, suitable for high-rise shelves or dense storage.

(2) Materials and processes

Common materials: Q235 carbon steel, galvanized steel.

Manufacturing process: cold rolling, welding reinforcement (some heavy columns are reinforced internally).

Surface treatment: spray coating (rust-proof + beautiful), hot-dip galvanizing (corrosion-resistant)

Introduction to round tube stacking columns

Round tube stacking columns refer to storage shelf columns that use round steel tubes as the core support structure. They are widely used in logistics warehousing, production line material stacking, supermarket shelves and other fields. Compared with square tube columns, round tube columns have unique advantages in torsion resistance, plug-in flexibility, and safety. They are especially suitable for scenes that require frequent disassembly or dynamic force.

(1) Structural advantages

Strong torsion resistance: The round cross-section evenly disperses torque and is suitable for dynamic loads (such as mobile shelves and rotating racks).

Easy to plug in: Naturally suitable for socket-type assembly (such as plug-in stacking racks), the disassembly and assembly speed is faster than square tubes.

No-edge design: Avoid scratching goods or personnel, and higher safety (suitable for areas with dense traffic).

(2) Materials and processes

Common materials: Q235 carbon steel, galvanized steel.

Manufacturing process: cold rolling, welding reinforcement (some heavy columns are reinforced internally).

Surface treatment: spray coating (multiple colors available), hot-dip galvanizing (corrosion resistant).

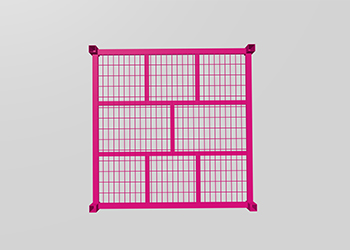

Standard folding stacking rack: four-column structure with guardrail, suitable for regular box goods.

Grid stacking rack: side net + back net design to prevent small items from falling.

Load-bearing requirements: Select the corresponding column thickness according to the weight of the goods.

Size matching: Make sure the unfolded size of the shelf matches the pallet or goods.

Size: Customized according to product type, weight, warehouse size.

Color: Customized according to your preference.