Racks for Tyres

We produce folding stacking racks, tube stacking racks and pallets for the world. We can help you choose the best storage solution. We have rich experience to provide you with one-stop service, including design, customization, production, and problem solving. We look forward to our cooperation.

Tire stacking racks are a type of storage equipment specifically used for storing, handling and sorting tires. They are mainly used in tire manufacturers, logistics warehouses, auto repair shops and other places. It can effectively save space and improve the efficiency and safety of tire storage. The following is a detailed introduction to tire stacking racks:

1. Main types

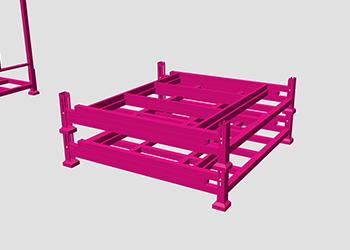

Insertion-type stacking racks

Structure: Similar to the combination of shelves and pallets, tires can be placed flat or vertically on pallets and transported with forklifts.

Features: Strong load-bearing capacity, suitable for large-scale storage, especially for heavy tires (such as engineering machinery tires).

Applicable scenarios: tire warehouses, logistics centers.

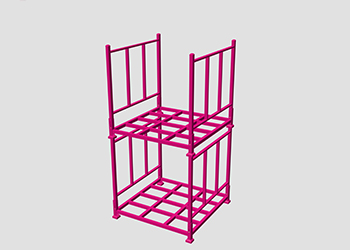

Foldable stacking racks

Structure: Foldable design, can be folded up when not in use to reduce space occupied.

Features: Flexible and portable, suitable for temporary storage or places with limited space.

2. Core features

Space optimization: Multi-layer design maximizes the use of vertical space and reduces ground occupancy.

Protect tires: Avoid direct contact with the ground, prevent moisture, deformation or pollution.

Convenient access: The layered structure facilitates classification and management by specification and model, and quick access.

Durability: Mostly made of steel or high-strength plastic, with good load-bearing performance and no deformation after long-term use.

Safety: The stable structure prevents the tire from slipping, and some designs are equipped with anti-slip pads or guardrails.

Standard folding stacking rack: four-column structure with guardrail, suitable for regular box goods.

Grid stacking rack: side net + back net design to prevent small items from falling.

Load-bearing requirements: Select the corresponding column thickness according to the weight of the goods.

Size matching: Make sure the unfolded size of the shelf matches the pallet or goods.

Size: Customized according to product type, weight, warehouse size.

Color: Customized according to your preference.